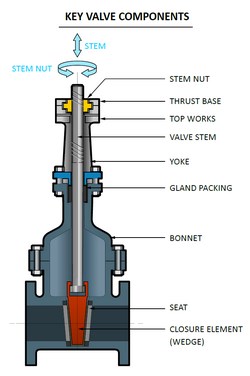

A major problem with stem nut thread failure is that stem position is usually interpolated from the number of stem nut rotations. If the stem nut threads strip out, the stem nut will still turn but will give a false indication of position to the control room. Such a failure of control and indication on a valve could cause a critical safety or environmental incident. This paper reviews approaches to stem nut maintenance and introduces a more scientific approach to measure stem nut thread wear.

Regulator & Steam Solutions

Safe Home Maintenance Brochure by Arbor Move Realtors - Issuu

PDF) A Review of Techniques to Mitigate Jamming in Electromechanical Actuators for Safety Critical Applications

Lessons learnt and best practices of managing coastal risk from local communities' perspectives: technical report

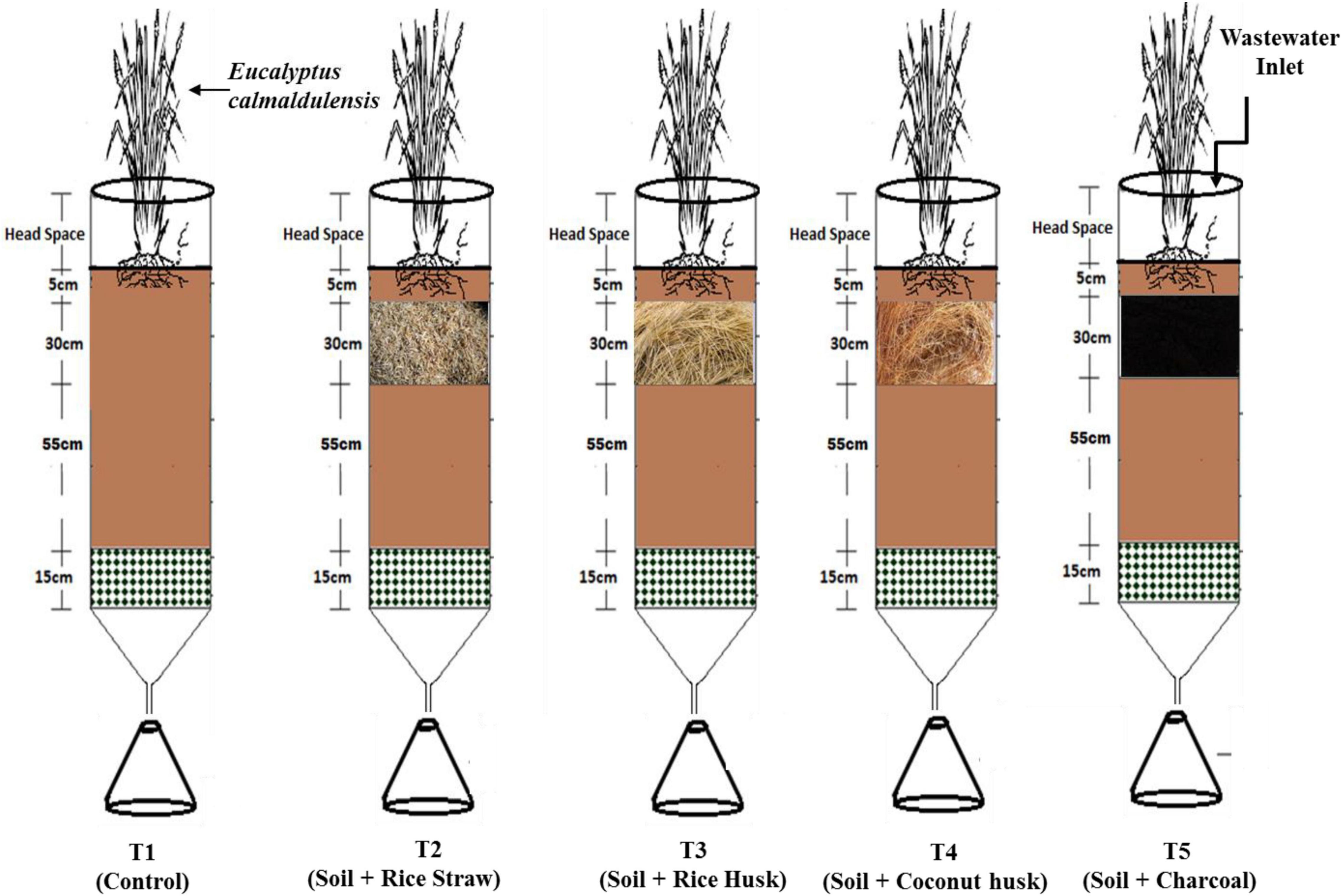

Frontiers A Modified Lysimeter Study for Phyto-Treatment of Moderately Saline Wastewater Using Plant-Derived Filter Bedding Materials

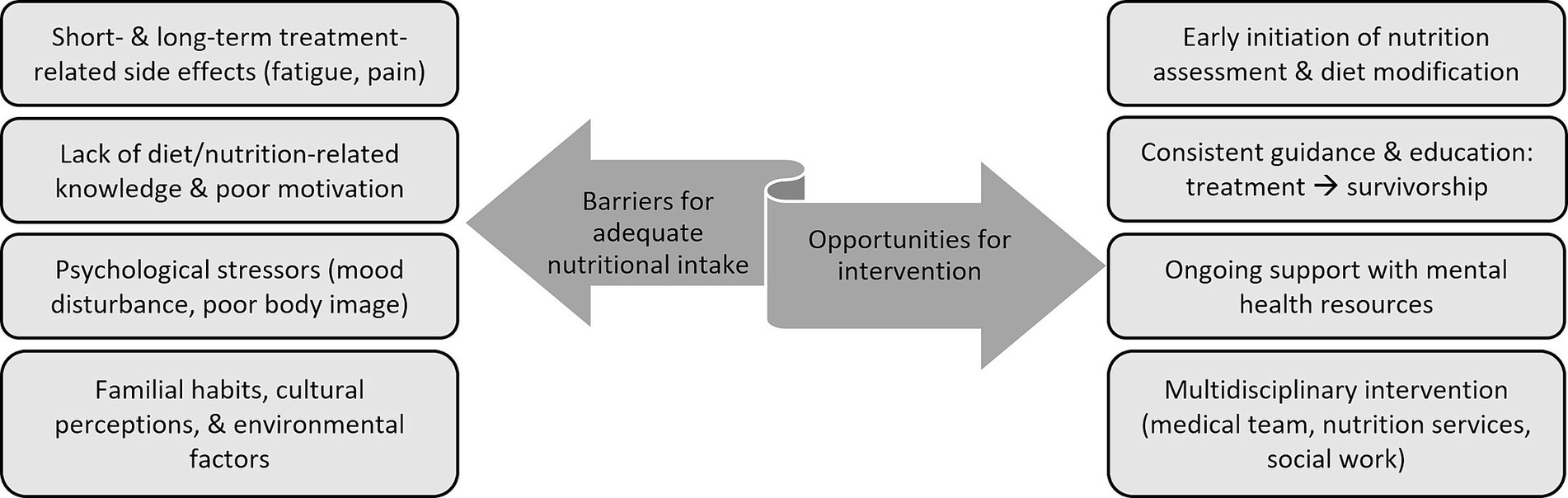

Frontiers Nutritional assessment and dietary intervention among survivors of childhood cancer: current landscape and a look to the future

From Small Steps to Giant Leaps - Engineers Without Borders UK

Sand production: A smart control framework for risk mitigation - ScienceDirect

fesbc – FESBC – Forest Enhancement Society of BC

Fix a Leaking Frost-Proof Faucet

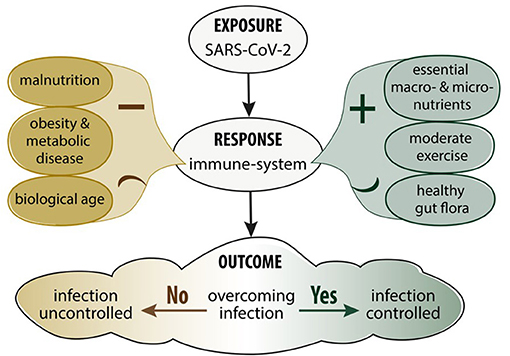

Frontiers Nutritional Impact and Its Potential Consequences on COVID-19 Severity

Event Rules - FRC Q&A

Mitigating MOV stem nut failure through proper maintenance and wear measurement - Valve World

Credited Responses: The Future of Ethical AI Design, Imagining the Internet